One day last spring I was cleaning up after a fish butchery class at Elawa Farm, a non-profit in Lake Forest, IL. I offer classes that cover beef primals and whole lamb, but the ones where I have to work the hardest as an instructor are chicken break-down and fish butchery. Like chickens, small fish are slippery. The boning knives we use in class are sharp, short, built to work against muscle grain, connective tissue, and bone. The ergonomics of a boning knife are different from chef knives, which are meant to cut down towards the flat, grounded surface of a cutting board. This is a big adjustment even for those with good knife skills, and it takes practice to master. More practice than you can gain in a two hour class. Fish class entails four cutting stations, four people handling sharp knives at once, fingers trying to gently grip a small, slippery filet as they learn to run the tip of the knife against the flexible bones of the spine. I keep the bandaids close, though over the course of seven years of teaching I’ve only had to break them out a handful of times and never for anything more than a nick.

I’m tired after class - I didn’t bring an assistant, and I probably should have. I’ve been talking constantly for two hours, remembering names and faces, keeping my eyes on four sets of hands at once. I hovered respectfully, I interjected tactfully, I diverted minor disasters at the critical moment without letting on that danger loomed, I wrapped filets and labeled them. I fielded questions about best places to buy fish in the city and beyond, about my favorite restaurants, and the question I get asked every class, “so, how did you get into butchery??” I cooked, I cleaned, I shook hands, I finally went pee, I finally drank some water, I took out the trash.

I get a phone call from a Kentucky number as I’m walking the last of my gear to my car for the hour drive back to the city. In a generous mood, I answer, and the voice on the other end asks if they’ve reached the Chicago Meat Collective. One element of being the owner of a very small business is that my phone number and address have made their way into public domain. I say yes.

The call lasts most of the drive home, and I switch the phone from ear to ear as I buckle my seatbelt and enable bluetooth. This woman is barely giving me a moment to breathe. She has a barrage of questions prepared, and her approach feels like an inquisition. I keep my voice level as I answer her line of questions one at a time, trying to lower the intensity of the conversation while I work to figure out what she wants from me. The gist is that her husband needs work, wants to become a butcher (or she wants him to), and they’re looking for training. She wants to know if the CMC’s classes will give her husband the skills he needs to get a job.

I’ve fielded similar inquiries before (never delivered with this level of vigor, or, frankly, apparent distrust), and it brings us straight to the heart of a matter I spend a lot of time thinking about. What does it mean to be an “educator” when you don’t work for an institution, when no certificate or degree arises from your teaching? Butchery was once a union-protected trade and butchers played an essential role in the food supply chain. Now much of that work has been deconstructed from a whole craft to a set of menial tasks to be repeated by replaceable laborers on a factory line. There is no longer a butcher’s union, though some people who cut meat professionally fall under more general unions that protect grocery workers or factory labor. There are no existing trade schools for butchery at this point in time in the USA (though there are some great meat science and meat processing programs, as well as a couple apprenticeship and extension programs out there, scroll down for links).

As I work backwards from her opening questions - will the students learn to use saws, what kinds of knives do the students use - I learn that she is a pastor at a Baptist church outside of Louisville and that her husband is looking for work after serving in the military. My answer to most of her questions is a qualified no - the students will use hand-saws but will not use bandsaws or any industrial equipment. The students will learn techniques of seam butchery and the whole animal approach, they will not be schooled in universal product codes for each cut. Now that I’ve disarmed her by essentially refusing to sell her my services, explaining that the CMC does not offer professional butchery training, she subtly shifts from interrogator to passionate concerned citizen, eager to discuss her vision for a better meat supply. She sees butchery as honest work, plus she’s interested in homesteading and raising her own meat animals. She’s dreaming big, envisioning a kind of church-led, for the community, locally-sourced butchery service. She’s dissatisfied with her current access to meat - it’s too expensive, dubious in quality, unreliable (will the grocery store meat supply survive another pandemic?) She’s ready to take things into her own hands.

She’s preaching to the choir, but I don’t have satisfying solutions to offer. I explain that there is no official pathway to becoming a butcher, no single degree or certificate recognized universally by employers. I’ve also gently alerted her to the fact that entry level butchery jobs are often menial (consisting mostly of wrapping cuts in styrofoam and checking dates), sometimes physically taxing (long hours on your feet, heavy lifting, repetitive motions of cutting), usually both. While pay is better than some other entry level retail or grocery gigs, it’s not particularly well compensated. What is the appeal of butchery? I nudge her to turn her interrogation inward.

When I finally get off the phone, I have to laugh at myself. I was tired before, now my mind is buzzingly numbed. I just used my whole arsenal of soft skills to help a very eager possible client understand that I most likely can’t provide them with what they’re looking for and that perhaps they should consider abandoning their pursuit of butchery skills altogether. I know those soft skills of mine are honed as ever because the conversation ends with the pastor volunteering to fly me down to Louisville, lodge me in her home for a weekend, and pay my stiff hourly private instruction rate to walk her husband through a whole hog carcass over two days. I agree we can explore a private session, doubtful that it’s a scenario I’m totally comfortable with and equally doubtful that she’ll follow through. She does not.

I got into butchery right out of college. Disinterested in the more traditional progression from BA to MA to PHD, I’d caught the bug for manual labor and was captivated by the depth and breadth of what I didn’t know about where food came from. The initial spark came from an afternoon session with the Portland Meat Collective at the end of my senior year, followed by a sweaty afternoon the summer after I graduated spent in the basement of Bubby’s in NYC, working with their head butcher Liz who had no problem telling me she was sick of soft-handed liberal arts educated kids with stars in their eyes dreaming of doing some “real work.” I let that slide off my back and vowed to learn as much from her as I could.

As with any craft, learning butchery requires hours of repetition. Therein lies the fundamental challenge of teaching butchery - the raw material needed for practice is expensive, perishable, and requires the sacrifice of an animal’s life. In fish class, each student cuts two small fish, taking home the filets, usually about a pound in total. The filets from the second fish are almost always a little neater than the first. Even that little bit of experience builds confidence and the beginnings of muscle memory - how best to grip the knife, how much pressure to exert, how to stabilize the fish with your other hand. Chicago Meat Collective aims to guide students through the initial burst of understanding and confidence that comes with doing something for the first time. Creating an opportunity for folks to confront their icks (raw meat, germs, food with a face) and follow their curiosity towards a deeper understanding of meat, which is so deeply wound in cultural traditions, environmental and ethical concerns, and what it means to be human, is the goal of every CMC class or event.

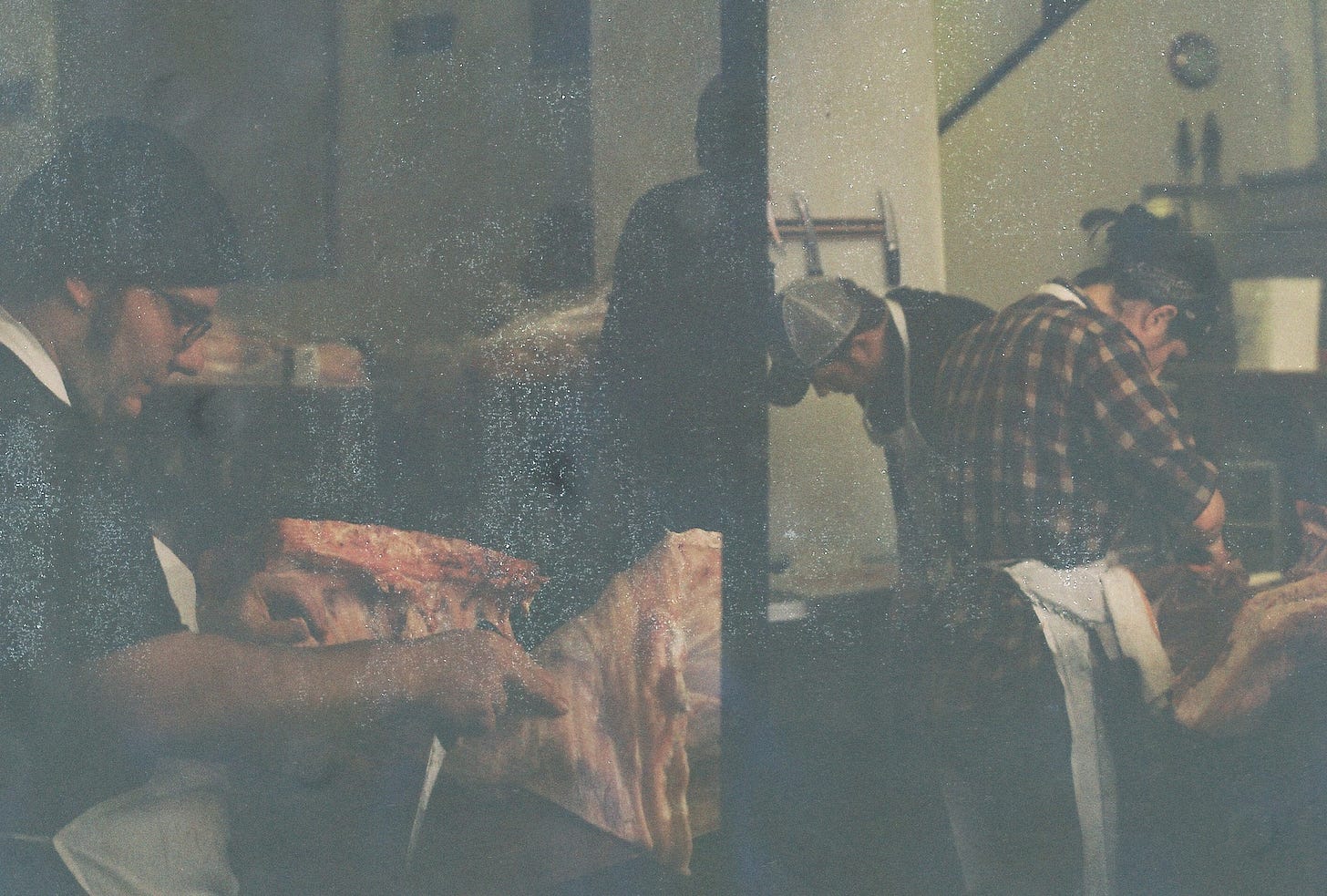

As I explained to the inquisitive pastor from Kentucky, our classes don’t train people to become butchers. After my two brief brushes with whole animal butchery in the spring and summer of 2013, I still barely knew the names of the pork primals and my knife skills were non-existent. I got my hours in a kind of old fashioned way, through unpaid stages at a small shop in Chicago. I showed up once a week on my day off from the coffee shop I worked at in Evanston and blundered along through bus tubs of trim (scraps of meat generated from breaking down the whole animal) with my single boning knife, my Danskos, and the pair of beloved army surplus canvas pants that became my work uniform.

I loved that job. I loved the shop talk, the weekly rhythm of receiving over 1000 pounds of raw meat on the hoof every Wednesday, our five person team working to get it broken down so it could fit into the small walk-in fridge, mopping the floor every night to Karma Chameleon. I can also say that my story is far from a blueprint to a fruitful career. I remained an unpaid stage for months before being hired on a 1099 at below minimum wage, something I naively didn’t interrogate at the time and could only agree to because I had family helping me with rent and living expenses. Though the shop eventually expanded and was able to make me an official employee with benefits, pay hovered around minimum wage and upward mobility was limited even after four years on the job.

“Keeping the craft alive” has a noble ring to it. It’s an often cited reason to possibly go broke pursuing the dream of becoming a capital B butcher, perhaps opening your own boutique butcher shoppe one day. The pastor from Kentucky had a bigger vision of food sovereignty, but her inquiry was directly motivated by the need get her husband a decent job. She thought butchery might be it. I found the best answer to her question had more to do with understanding what kind of jobs actually exist for so-called butchers than with how to get the appropriate training. Most of the small shops that pride themselves on capital B butchery exist in cities (Louisville has a great one in fact, Red Hog) and have very small staffs. Most grocery stores, from the independent ones to the chains, receive their meat Cryovac-ed by the cut, and their staff break those subprimals down into retail units, trim and portion cuts like tenderloin and ribeye, and perhaps grind meat fresh and make sausage. Slaughterhouses face a consistent labor shortage, but they are often located in rural areas with few amenities, and the work carries a stigma that can deter bright-eyed aspiring butchers.

Our industrial agricultural system is actively doing all it can to reduce the need for skilled human labor. This is most apparent at the largest scale, slaughterhouses and packing plants operated by the big four, industry giants that control the majority of the country’s meat supply. These companies can afford investments in infrastructure and equipment that prioritize almost unimaginable efficiency (according to this article, an updated Smithfield plant in North Carolina can slaughter 35,000 hogs a day). The effects of centralized, mechanized meat processing trickle down to the local grocery level - as plants can handle more and more of the labor from the kill all the way through to trimming, portioning, and packaging individual cuts, the work that remains to be done locally is diminishing. One of the most frequently posted jobs in large grocery chains is the role of meat clerk. A current job description on this hiring post from a Des Plaines, IL branch of Mariano’s reads “Perform general clean-up and stock work in the Meat department and provide customer service.” There is no mention of butchery work or meat cutting.

On a recent post for a meat department manager role at a Whole Foods branch in Chicago, one of the qualifications listed is “Certified Meat Journeyman or equivalent training” (this is the only mention of experience cutting meat, aside from requirements like “Thorough product knowledge”). Tellingly, the first Google hits for the search term “certified meat journeyman” come from reddit, a thread titled “how does becoming a journeyman work? r/Butchery” and a Ziprecruiter article title “What Is a Journeyman Meat Cutter and How to Become One.” The first line of the '“how to” is “There are no specific academic qualifications necessary for becoming a journeyman meat cutter,” followed by a quick reference to how “the formality of the role has decreased” since the term was coined when butchery was still a unionized trade. The article goes on to recommend learning on the job and then finding an apprenticeship program. Search butchery apprenticeship on Google and the first hit is also from reddit, though Whole Food’s in-house apprenticeship program comes up, as does a several months long program based in Tuscany, neither of which are registered with the U.S. Department of Labor and do not provide an “industry recognized credential.” The the website for the U.S. Bureau of Labor Statistics states “Butchers typically need no formal educational credential. They learn their skills on the job.”

What does this all add up to? People seeking work in meat processing, whether it’s because they value the disappearing craft, are inspired by a nostalgic vision of the cleaver-wielding butcher operating a local small business, or because they simply need a job, are facing a confusing landscape populated by minimum wage, entry level jobs with unclear pathways to professional development and advancement. Unaccredited meat classes popping up on google (like the ones I offer) don’t help clarify the situation, which is why I feel inclined to submit to interrogation from strangers calling my cell phone asking about job training.

Unlike some other fields reckoning with job loss in the face of AI and technological advancements, butchery has been effectively gutted for many decades, a process that began in the late 1800s with the rise of the original big four meat packers and the invention of the refrigerated railway car (see Red Meat Republic by Joshua Specht for a thorough history). Yet working as a butcher has enduring appeal, and on it we project our hope for the chance to make a difference individually and directly, expertly wielded blade in hand.

The meat industry is a big mess, and change is still necessary and possible. We still need butchers. When I started working with meat over ten years ago, the rallying cry was to champion small over large - small producers (“family farms” as people love to say), small businesses. It was also “eat less meat, but better quality,” a nimble side-step of the food access issues that result from the small margins of the local whole animal butcher shop and the barriers to scale that make it difficult for that model to compete with meat coming from the vertical, industrial system.

What I’ve found over the years is that the middle is the most promising area for real change in the industry - mid-size farms, co-ops, and meat brands, mid-size processors, mid-size distributors, especially ones that sell directly to the consumer, skipping the grocery store and holding onto more of their margins while responding to customers who are more comfortable shopping for food online post-covid. At the Carolina Meat Conference I attended last summer, Dr. Temple Grandin gave the final keynote speech. “Big isn’t bad, it’s fragile,” she repeated several times, and I believe that’s an important redirection for those interested in alternatives to the status quo. Instead of expending energy detailing the many sins against the planet, animals, laborers, and consumers that can be attributed to the “big” meat industry and simply proclaiming the inherent virtue of the small farm, we need to support and expand the infrastructure of the middle, keeping food access, quality jobs, and local supply chains at the front of our minds.

I’m inspired by operations like Home Place Pastures in Como, Mississippi, a vertical, direct-to-consumer retail meat business. They raise grass-fed beef, source from local producers who use similar practices, and run a USDA processing plant so that they can kill, cut, wrap, and ship meat nationwide directly from their community. You can hear founder Marshall talk in-depth about the business model and his personal story here. I’m inspired by Preservation Meat Collective, a processing and distribution business in the Pacific Northwest that connects exceptional producers with wholesale clients willing to pay, taking the burden of marketing and distribution off the farmer. I’m inspired by Nordik Meats, the Viroqua, WI USDA processor that let me spend three days with their team a couple years ago. If I were getting into the industry now, these are the kinds of businesses whose doors I’d be knocking on.

More resources on butchery education, etc.:

Apprenticeship, Job Training, and Extension Programs

Spreadsheet of programs and one-off classes from The Good Meat Project

Community Kitchen Pittsburgh/Unified Fields

Penn State Extension Butchery Apprenticeship Program (no current dates available)

SUNY Cobbleskill 4 week Meat Processing and Food Safety Program

University of Madison Meat Science Dept. Short Courses Offerings

Western Meat School - Online program produced by CSU extension and NMPAN

Industry Resources:

A really great write-up. Thank you for this!

Part of me wonders what my life would have become had I gone full force into my table bussing job at PQM in Chicago a decade ago instead of pursuing improv comedy at the time. Decisions were made though and, well, the rest is history.

McCullough, this is an incredible, informational piece about Butchery, and what it actually means. Your writing is so thorough, and yet comfortable to read. All that plus the fact that you are an impressive butcher yourself, having learned from the work you've done.

So looking forward to seeing you in a few weeks!